DIY Acoustic panels by yourself

How to make an acoustic panels for a sound recording home studio by yourself.

DIY Acoustic Panels do-it-yourself

How to make an acoustic panels for your sound recording home studio by yourself.

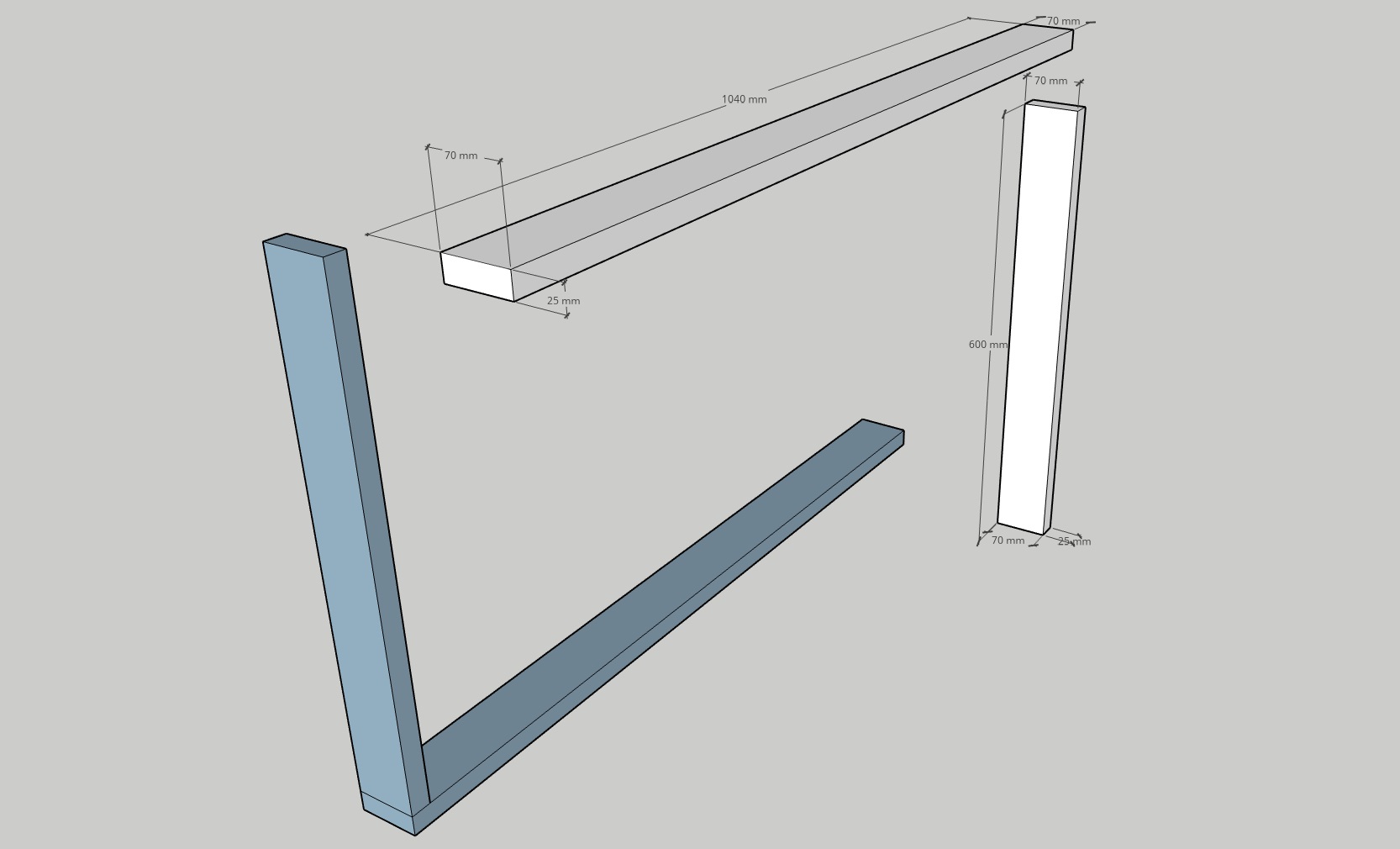

1. Material: wood

Height: 70

Thickness: 25

Lengths: 600 and 1040

Overall 4 wood pieces per panel:

2x 1040x70x25

2x 600x70x25

2. The internal acoustic element is rockwool, universal 75', dimensions 1000x600, not intended for physical influences, should be safe for the environment.

3. Fasteners: wood screws, length 60, 8 pieces per panel.

3.1 Screwdriver bit;

3.2 A drill for wood for the diameter of the screws, first you should drill holes, then twist screws;

3.3 Electric screwdriver-drill.

4. Upholstery:

front - cotton fabric (texture and type of material affects the acoustic characteristics)

rear - regular furniture spunbont

Minimum fabric sizes with a margin for easy tension:

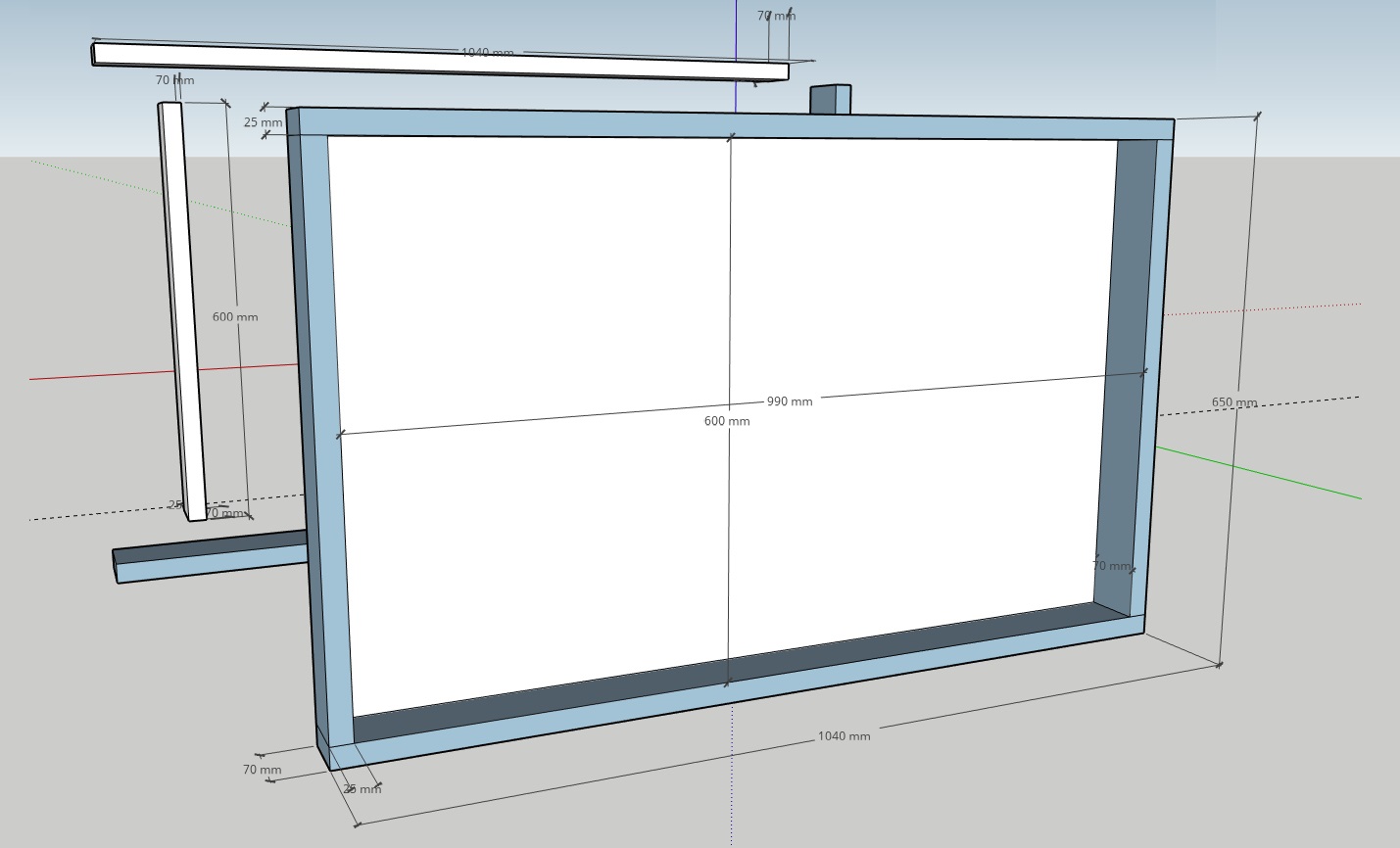

Front - just consider the sum of the lengths of the edges from edge to edge and add an extra on each side:

1. 25x2 (thickness of the board) + 70x2 (outer side face = height of the board) +650 (front length = 600 + 25 + 25) + extra mm to each side ~ 100

2. 25x2 + 70x2 + 1040 (full height) + extra

w 840 + extra = ~ 1040

h 1230 + extra = ~ 1430

Total: 1430x1040, or you can go 1400x1000 (depending on the store and price)

Spanbont - 1040x650 + extra to each side (+50), min. ~1090x700

5. The stapler and staples, in my case staples are 12mm (53) or 8mm.

The internal size of a setup is 990x600, depth 70 (board height), this determines the size of the rockwool. In my case, the dimensions of the boards are chosen so that a 1000x600 by 75 sheet fits inside, list of rockwool is specially chosen longer(height) and slightly thicker, in order to better hold inside. You can go without transverse slats in construction, everything keeps well on the tighten fabric.

1 - unit of measure MM

(ATTENTION! - do not confuse by buying a wrong type of building material, that can be harmful to your health, carefully read the specifications and consult with professionals)

(ATTENTION! - use personal protective equipment when performing work, observe safety precautions)

(ATTENTION! - rockwool should not be compressed too much, or seriously physicaly influenced, it should be relatively free in the construction, just cut the excess with paper knife, liquid should not get there)

(ATTENTION! - it is necessary to tighten fabric quite strongly, if possible, not only for the nice looking, but also for better rockwool stability)

(ATTENTION! - the spanbont tears quite easily when tighten, so you need to pull it carefully)

(ATTENTION! - all the data provided is informative only, the result depends on the selected materials you chose, the quality of the work you have done and the good preparation for that, the acoustic characteristics also depends on the selected materials and carefully studied specifications by you, also depends on environment where you planning to use panels)